4 minutes a) AC Motors (Alternating Current Motors):

“Electric motors consume over 60% of the electricity used in the industrial sector, making them a significant focus for energy efficiency initiatives in industries worldwide.”

1. Introduction:

Electric motors convert electrical energy into mechanical motion through the interaction of electric currents and magnetic fields.

There are two main types of electric motors:

a) AC Motors (Alternating Current Motors):

- Induction Motors: These motors rely on electromagnetic induction to produce rotational motion. They are widely used in industrial and commercial applications due to their robust design, simplicity, and cost-effectiveness and more common than synchronous motors. Induction motors are used in electric pumps.

- Synchronous Motors: These motors run at a constant speed synchronized with the frequency of the power supply and are commonly used in applications requiring precise control.

b) DC Motors (Direct Current Motors):

- Brushed DC Motors: These electric motors utilizes brushes and a commutator for rotational motion. They are not common in the industry but typically found in small appliances and low-cost consumer electronics.

- Brushless DC Motors: They use electronic commutation for improved efficiency and reliability. They are widely favoured in industrial application e.g. robotics, electric vehicles, HVAC systems, and industrial automation.

- Permanent Magnet DC Motors: This type of motors Feature rotor permanent magnets and no field windings. These motors are applied in industrial machinery, actuation systems, medical equipment, and renewable energy applications like wind turbines.

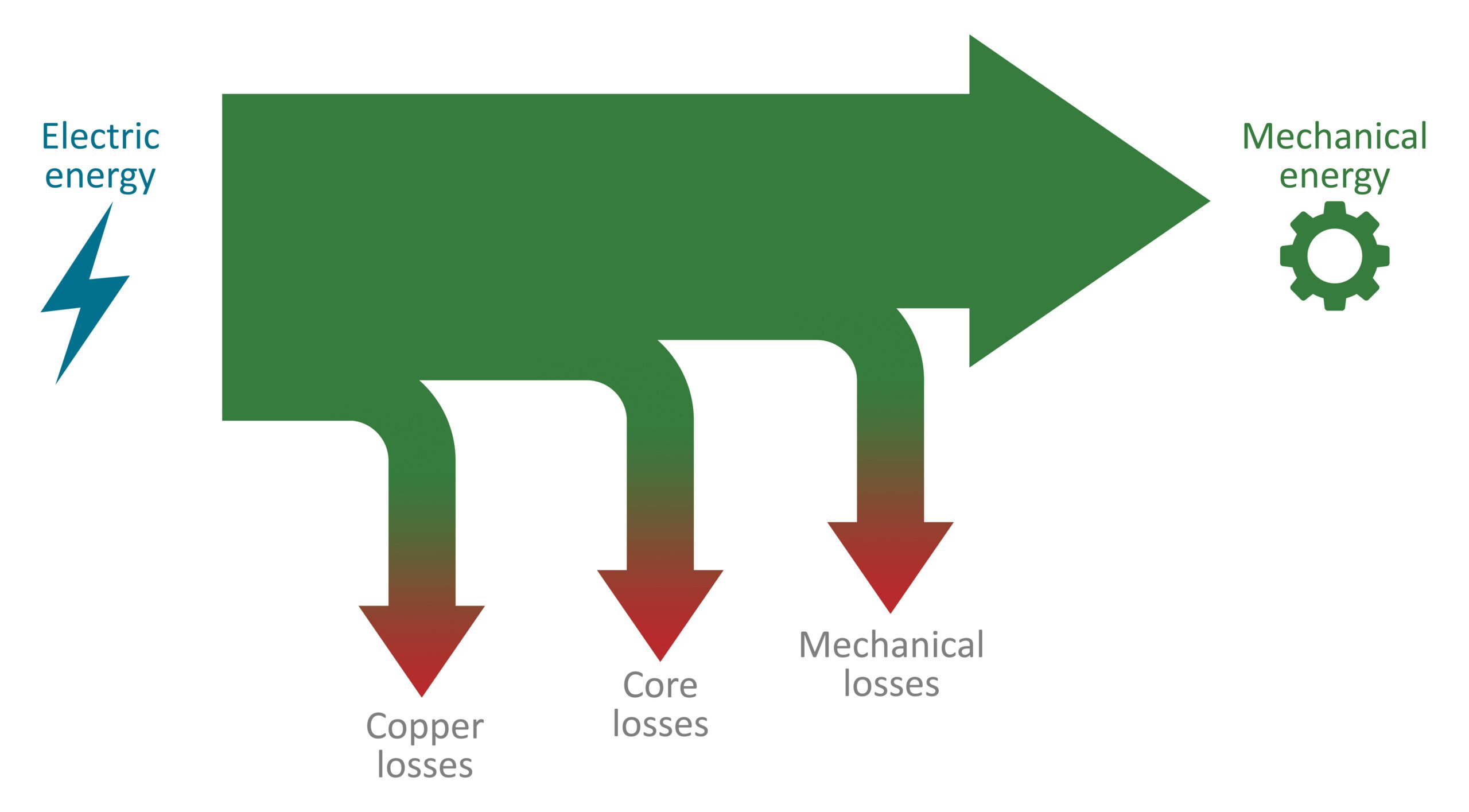

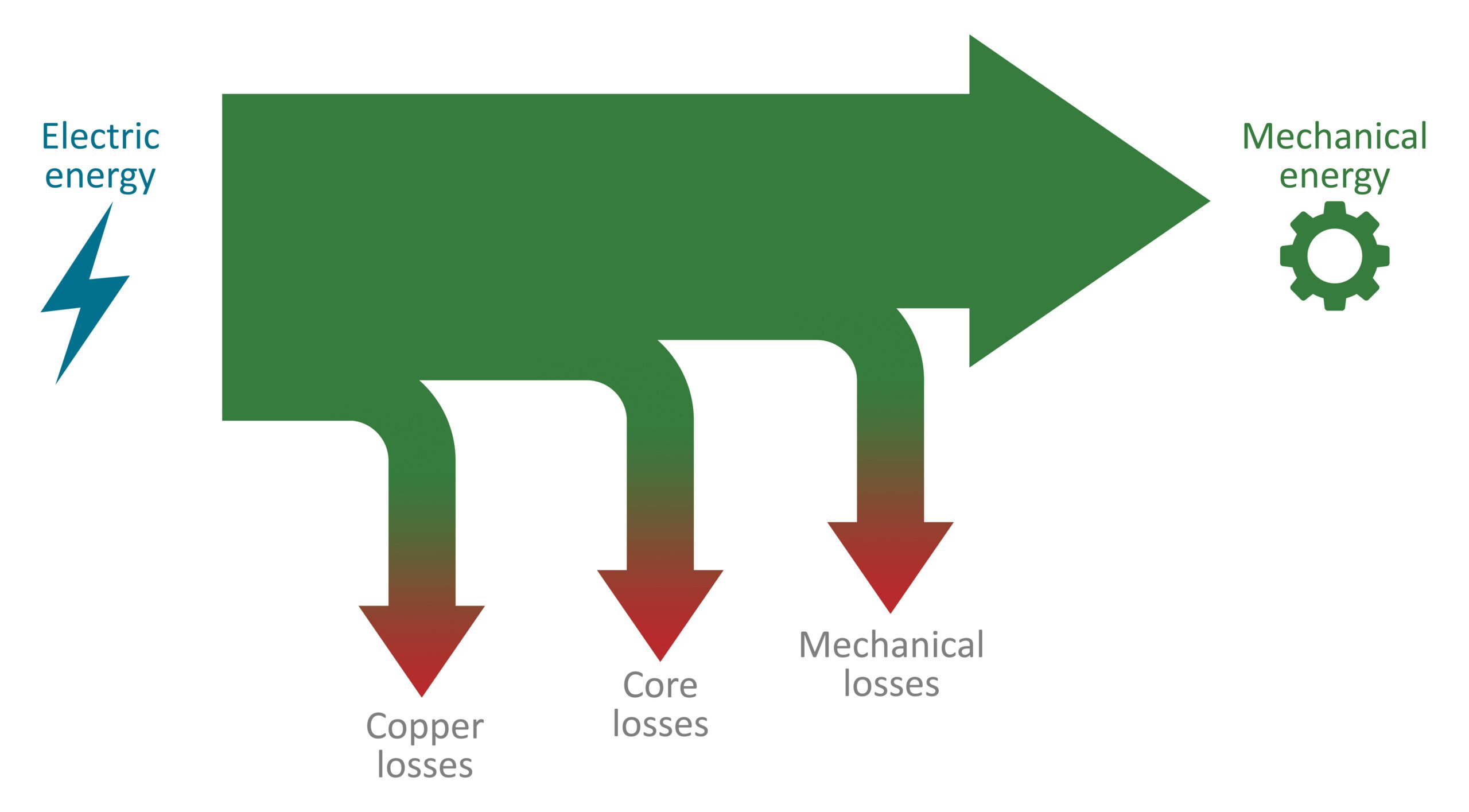

2. Electric Motor Losses

Electric motors have an efficiency of 70 – 95% whereas the lost energy is mostly dissipated as heat. Understanding the losses is crucial for optimizing motor performance and to cut energy consumption.

There are three main categories of losses (explore the interactive image bellow for more information):

- Copper losses

- Core losses

- Mechanical losses

Besides addressing these losses directly, also advanced controls provide ample saving opportunities as they can ensure that motors only operate when the mechanical energy is actually required.

3. Optimizing Motor Efficiency

Four major interventions allow to increase the motor efficiency ( for details check the interactive graphic below):

- Optimizing power terminals

- Improving motor environments

- Enhancing mechanical transmission systems

- Thoughtful motor selection

If you seek a professional motor status evaluation – request an account for the eeaser accelerator.